Opening Sale! All products are 10% OFF!

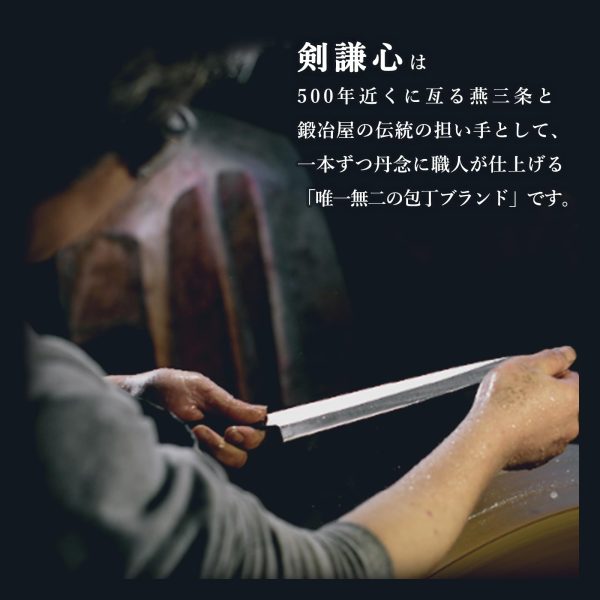

Kenshin Kenshin Santoku Knife DP Kasumiryu Steel Split Clasp Santoku Knife 170mm VG10 Steel Laminated Reinforced Handle Double-edged Knife Tsubame-Sanjo Knife Sanjo Uchihamono Traditional Crafts French Knife Chef's Knife Niigata Cooking Artisan Chef Professional Household Use

$246.35

A proud technique of Japan, the kasumi-nagashi processing involves alternating high-carbon stainless steel and low-carbon stainless steel, creating a beautiful pattern.

It boasts outstanding durability for long-term use, resistant to changes over time, and the handle is less prone to wear.

The joint between the blade and the handle is equipped with a durable bolster that is sanitary and resistant to dirt accumulation.

The bolster, the metal joint area between the handle and blade, uses 18-8 stainless steel (18% chromium, 8% nickel), known for its excellent anti-rust and passive film properties.

This is the most commonly used multipurpose kitchen knife in Japanese households.

It effortlessly handles any scene or ingredient, including meat, fish, and vegetables.

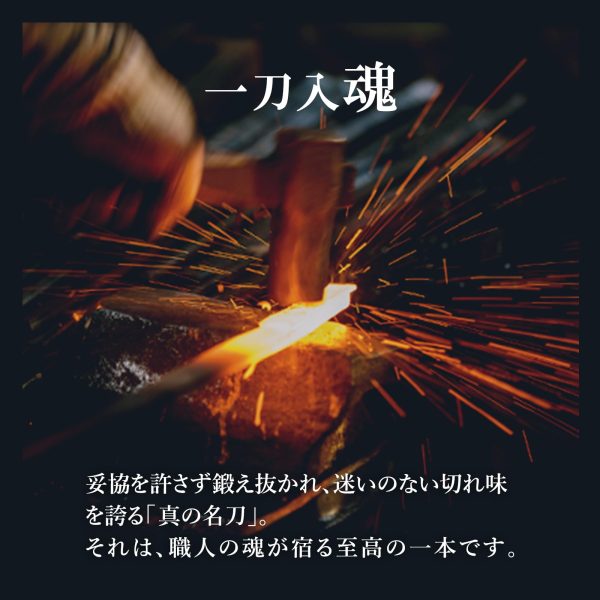

The core material uses VG10 steel, known for its sharp cutting edge and sturdy blade.

The double-edged style, said to have been introduced from the West, fits various culinary cultures, both Japanese and Western.

It is suitable for both right-handed and left-handed users.

Even cooking beginners will find it easy to handle.

The Santoku knife features a rounded tip, making it exceptionally easy to cut.

The handle incorporates laminated reinforced materials, also used in outdoor knives.

[What is kasumi-nagashi?] Kasumi-nagashi is a processing method that layers high-carbon and low-carbon stainless steel alternately in multiple layers, giving the blade surface subtle patterns and color variations.

The multi-layered structure pattern created by the metals is said to resemble flowing mist, hence its name.

The entire blade becomes resistant to oxidation, allowing it to withstand external shocks and rust while cutting materials precisely as intended.

[What is DP?] DP refers to a metal structure using DP cobalt alloy steel, which is a dual-phase type steel material where soft and hard parts coexist.

DP derives from the English term “Decarburization Prevention,” representing a technique that prevents the deterioration of hardness due to carbon migration between composite materials.

This technology is applied to high-grade materials among the inserted materials.

Additional information

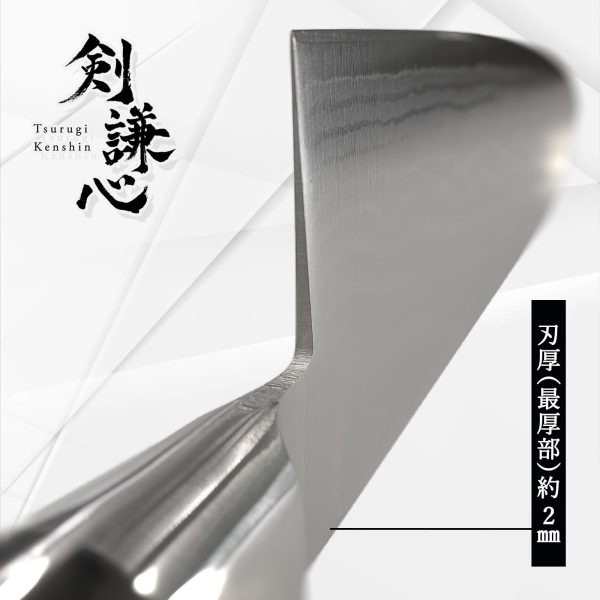

| Weight | 440 g |

|---|---|

| Dimensions | 356 × 80 × 30 mm |